Case Study: RH Bin Level Indicator in Portable Concrete Batch Plant

Midwest, USA

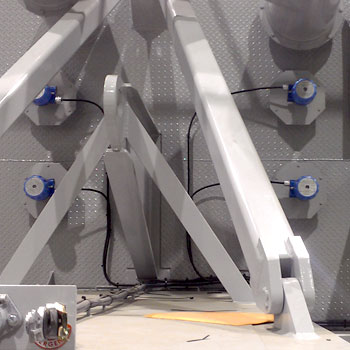

Concrete batching plants provide for the combination of cement powder, water, aggregate and often additives like flyash. Many batching plants are fixed and do not move, but many are portable being able to be setup, used, taken down and then moved to another jobsite as needed by the owner. In these portable plants there is the added stress of multiple setup and transport to different sites to all the equipment on the silos, such as the bin level indicators. We are pleased to be a part of several plant manufacturers batching plant level controls such as the one shown here.

Problem Summary

High and low level indication and control are required in cement and ingredient or additive bins and silos within a concrete batching plant. The need for proper and accurate filling control is essential. Side mounting is not usually possible so both high and low level indicators need to be top mounted with extensions.

Solution

Model RH rotary paddle bin level indicators are standard with several concrete plant manufacturers for use in portable plants. They are top mounted with extensions and also can be side mounted. Insertable folding paddles are sometimes used but it is common to use fixed heavy duty paddles as well. The RH provides reliable level detection and is rugged enough for these difficult installations. Rotary paddle technology is the most universal point level sensor technology for powder and bulk solids. It is very capable of operating in this “portable” environment and the dust within the silos containing cement and flyash powders. The Model RH units provide local LED indication of normal/alarm status, a DPDT relay output that is fail-safe on power failure, four shaft bearings and many other features for long life. They have been successfully installed and used in numerous portable and fixed concrete batching plants.

Model RH rotary paddle bin level indicators are standard with several concrete plant manufacturers for use in portable plants. They are top mounted with extensions and also can be side mounted. Insertable folding paddles are sometimes used but it is common to use fixed heavy duty paddles as well. The RH provides reliable level detection and is rugged enough for these difficult installations. Rotary paddle technology is the most universal point level sensor technology for powder and bulk solids. It is very capable of operating in this “portable” environment and the dust within the silos containing cement and flyash powders. The Model RH units provide local LED indication of normal/alarm status, a DPDT relay output that is fail-safe on power failure, four shaft bearings and many other features for long life. They have been successfully installed and used in numerous portable and fixed concrete batching plants.

Contact us with questions or browse all of our available products here.