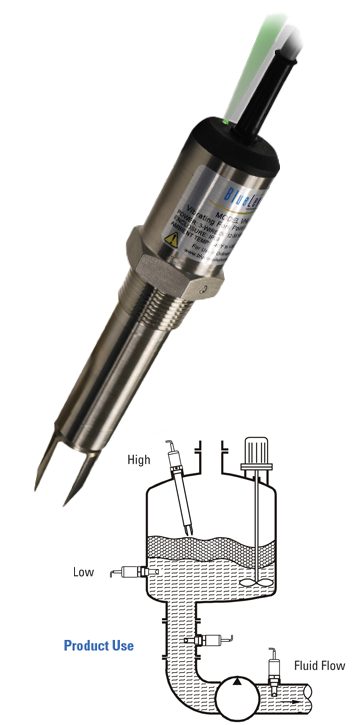

MODEL VHL MINI

Miniature Vibrating Fork Point Level Sensor for Liquids

Using the most ideal technology for a very wide range of liquids and slurry materials, the VHL Mini is a miniature version of the Model VHL vibrating fork point level sensor. It is specifically for use detecting the presence and absence of liquid and slurry materials and providing input to a PLC or control system. The Model VHL Mini provides a 2-wire AC or 3-wire DC solidstate output for use in switching low current loads, such as a relay coil, LED light or as an input to a PLC or other type of control system. This unit is available with a range of probe lengths and is economical and highly reliable.

Polished vibrating fork is standard

PFA coated or hygienic extreme-polish available

2-wire AC or 3-wire DC (NPN/PNP) solid-state output

External operational test function

High process temperature of 266°F (130°C)

Unaffected by dielectric constant, conductivity, viscosity, pressure and temperature

Miniature compact stainless steel housing

Prewired 3m long cable

IP68 (NEMA 6P) rated enclosure

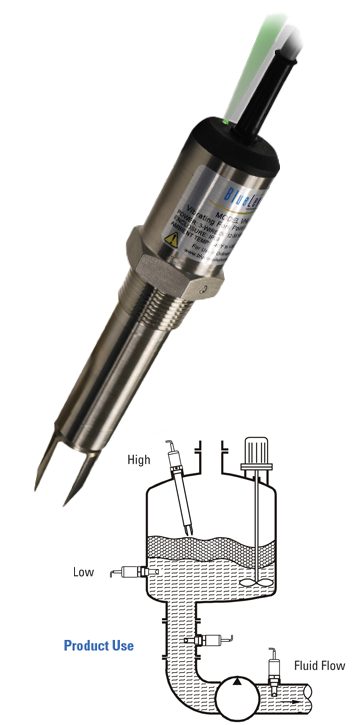

MODEL VHL MINI

Miniature Vibrating Fork Point Level Sensor for Liquids

Using the most ideal technology for a very wide range of liquids and slurry materials, the VHL Mini is a miniature version of the Model VHL vibrating fork point level sensor. It is specifically for use detecting the presence and absence of liquid and slurry materials and providing input to a PLC or control system. The Model VHL Mini provides a 2-wire AC or 3-wire DC solidstate output for use in switching low current loads, such as a relay coil, LED light or as an input to a PLC or other type of control system. This unit is available with a range of probe lengths and is economical and highly reliable.

Polished vibrating fork is standard

PFA coated or hygienic extreme-polish available

2-wire AC or 3-wire DC (NPN/PNP) solid-state output

External operational test function

High process temperature of 266°F (130°C)

Unaffected by dielectric constant, conductivity, viscosity, pressure and temperature

Miniature compact stainless steel housing

Prewired 3m long cable

IP68 (NEMA 6P) rated enclosure

Principal of Operation

Model VHL Mini vibrating fork level switches are suitable for level detection of a wide range of liquids. The operation principle is based on an electronic circuit exciting piezoelectric crystals, thereby making the fork probe vibrate. As the fluid or medium reaches and covers the fork its vibration changes, or stops completely. The fork will start vibrating again as the fluid sets it free. The electronics sense the change of vibration and causes the solid-state output to change state.

Application and Use

Mounted on pipes or tanks the filling and emptying of vessels can be controlled using the Model VHL Mini as they can generate alarms providing overfill or dry run protection where input to PLC’s, Controls Systems is required, and where switching low current loads is needed (refer to technical specifications).

Technical Data

| Power Supply | 2-Wire AC 20-255VAC 3-Wire DC 12-55VDC |

| Consumption | AC: Load Dependent DC: <0.6W |

| Wire Connection | 3m Prewired Cable |

| Enclosure Protection | IP68 (NEMA Type 6P) |

| Process Density | ≥ 0.7 S.G. (0.7 g/cm³) |

| Maximum Pressure | 588 psi (40 bar) |

| Maximum Viscosity | 10,000 cSt (mm2/s) |

| Medium Temperature | -40⁰F to +266⁰F (-40⁰C to +130⁰C) |

| Ambient Temperature | -22°F to +158°F (-30°C to +70°C) |

| Local Indication | Bi-Color LED Alarm – Red. Normal – Green |

| Output | AC: 350mA Maximum DC: NPN/PNP 350mA Maximum |

| Material | 316Ti Stainless Steel (DIN 1.4571) |

| Certifications | CE Mark |

More Information

Click here to download product line PDF’s

Standard Sensor Model Includes

- Threaded or Tri-Clamp process connections

- Short Probe (2.7″/69mm long)

- Standard Probe (4.9″/125mm long)

- Long Probe (7.9″/200mm long)

- Extended Probe (12″-118″/300mm-3,000mm)

- Ordinary Locations

Principal of Operation

Model VHL Mini vibrating fork level switches are suitable for level detection of a wide range of liquids. The operation principle is based on an electronic circuit exciting piezoelectric crystals, thereby making the fork probe vibrate. As the fluid or medium reaches and covers the fork its vibration changes, or stops completely. The fork will start vibrating again as the fluid sets it free. The electronics sense the change of vibration and causes the solid-state output to change state.

Application and Use

Mounted on pipes or tanks the filling and emptying of vessels can be controlled using the Model VHL Mini as they can generate alarms providing overfill or dry run protection where input to PLC’s, Controls Systems is required, and where switching low current loads is needed (refer to technical specifications).

Technical Data

| Power Supply | 2-Wire AC 20-255VAC 3-Wire DC 12-55VDC |

| Consumption | AC: Load Dependent DC: <0.6W |

| Wire Connection | 3m Prewired Cable |

| Enclosure Protection | IP68 (NEMA Type 6P) |

| Process Density | ≥ 0.7 S.G. (0.7 g/cm³) |

| Maximum Pressure | 588 psi (40 bar) |

| Maximum Viscosity | 10,000 cSt (mm2/s) |

| Medium Temperature | -40⁰F to +266⁰F (-40⁰C to +130⁰C) |

| Ambient Temperature | -22°F to +158°F (-30°C to +70°C) |

| Local Indication | Bi-Color LED Alarm – Red. Normal – Green |

| Output | AC: 350mA Maximum DC: NPN/PNP 350mA Maximum |

| Material | 316Ti Stainless Steel (DIN 1.4571) |

| Certifications | CE Mark |

More Information

Click here to download product line PDF’s

Standard Sensor Model Includes

- Threaded or Tri-Clamp process connections

- Short Probe (2.7″/69mm long)

- Standard Probe (4.9″/125mm long)

- Long Probe (7.9″/200mm long)

- Extended Probe (12″-118″/300mm-3,000mm)

- Ordinary Locations

Ordering Information

Final Assembly Part Number Structure

Ordering Information

Final Assembly Part Number Structure

1 – 2.7″ (69mm)

2 – 4.9″ (125mm)

3 – 7.9″ (200mm)

4 – Extended (12″ – 118″)

2 – 2-Wire AC

3 – 3-Wire DC NPN/PNP

1 – 1″ NPT

2 – 1-1/2″ Tri-Clamp

1 – 2.7″ (69mm)

2 – 4.9″ (125mm)

3 – 7.9″ (200mm)

4 – Extended (12″ – 118″)

2 – 2-Wire AC

3 – 3-Wire DC NPN/PNP

1 – 1″ NPT

2 – 1-1/2″ Tri-Clamp