MODEL RH/RHX

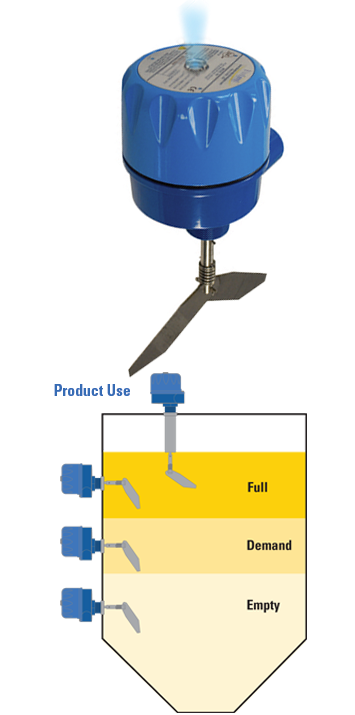

Rotary Paddle Bin Level Indicator

Our industry standard workhorse level detection sensor for powders and bulk solids – reliable, low maintenance, high value and high reliability.

These rugged and reliable rotary paddle bin level indicators are the most universal sensor for detecting the presence and absence of bulk solids ranging in density from 5 to over 100 pounds per cubic foot (80 to 1600 kilograms per cubic meter). Model RH/RHX units are provided with fail-safe relay output, high intensity LED’s for local indication (RH only), an industry standard 1-1/4″ process connection, two conduit entrances and food grade materials of construction. All units are available with folding or fixed paddles for easy installation from outside the bin and can be top or side mounted.

SUPER BRIGHT LED’s locally indicate Normal / Alarm status

Rugged aluminum enclosure with powder coat finish (FDA Compliant)

Twist off cover

Selectable High/Low fail-safe output on power failure

Four bearing shaft assembly increases reliability and life

Internal bi-directional clutch protects motor

Various voltages

Automatic motor shut-off

DPDT relay output

Removable wiring terminals

Interchangeable with other brands accessories

Adjustable sensitivity (if needed)

Dual conduit entrances

MODEL RH/RHX

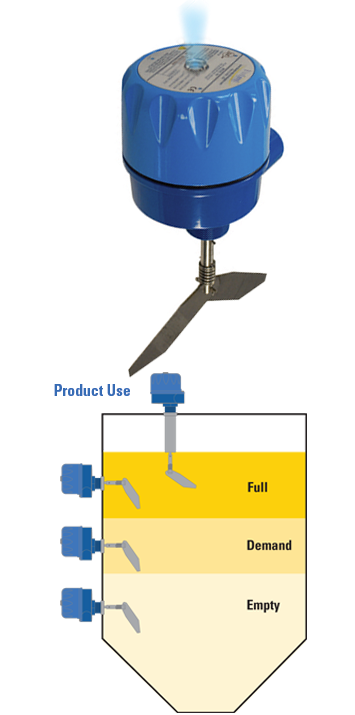

Rotary Paddle Bin Level Indicator

Our industry standard workhorse level detection sensor for powders and bulk solids – reliable, low maintenance, high value and high reliability.

These rugged and reliable rotary paddle bin level indicators are the most universal sensor for detecting the presence and absence of bulk solids ranging in density from 5 to over 100 pounds per cubic foot (80 to 1600 kilograms per cubic meter). Model RH/RHX units are provided with fail-safe relay output, high intensity LED’s for local indication (RH only), an industry standard 1-1/4″ process connection, two conduit entrances and food grade materials of construction. All units are available with folding or fixed paddles for easy installation from outside the bin and can be top or side mounted.

SUPER BRIGHT LED’s locally indicate Normal / Alarm status

Rugged aluminum enclosure with powder coat finish (FDA Compliant)

Twist off cover

Selectable High/Low fail-safe output on power failure

Four bearing shaft assembly increases reliability and life

Internal bi-directional clutch protects motor

Various voltages

Automatic motor shut-off

DPDT relay output

Removable wiring terminals

Interchangeable with other brands accessories

Adjustable sensitivity (if needed)

Dual conduit entrances

Principal of Operation

For several decades rotary paddle technology has been used as a method for detecting the presence and absence of bulk solid materials.

A robust synchronous motor drives a stainless steel output shaft at approximately 1 RPM. The paddle is attached to the shaft and rotates freely in the absence of material within the bin.

Material presence surrounding the paddle in the bin will impede its rotation and cause the state of the built-in relay contacts to change, indicating material presence. The built-in LED’s will change to indicate the status of the alarm condition.

Application and Use

High (full), low (empty), intermediate (demand) level indication, and plugged chute detection, are common applications within a wide variety of industries.

Prevention of bin overfilling and material outage conditions are typical uses of these devices. The Model RH and RHX rotary paddle bin level indicators can be used to detect materials with density from 5lbs/ft³ (80kg/m³) for low and intermediate level control applications and from 10lbs/ft³ (160kg/m³) for high level indication.

Example materials include plastic pellet, food stuffs, feed and their ingredients, grains, cement, aggregate materials, nuts, flour, resins, sand, coal, chemicals, limestone, wood, sawdust and many more.

Technical Data

| Housing | Die-cast aluminum, FDA compliant powder coat, NEMA Type 4X, IP65 |

| Process Temp | Up to 300° F (149° C) |

| Ambient Temp | -40° F to +158° F (-40° C to +70° C) |

| Sensitivity | Low Level ≥ 5lbs/ft³, High Level ≥ 10lbs/ft³, Adjustable setting |

| Motor Voltage | 24VAC, 115VAC, 230VAC, 12VDC or 24VDC |

| Output | DPDT Relay, 8A @ 250VAC |

| Process Connection | 1-1/4″ NPT powder coated |

| Bearings | Four (4) sealed bearings |

| Certifications | Ordinary Location; CE mark; Hazardous Location |

More Information

Click here to download product line PDF’s

Model RH/RHX Rotary Paddle Accessories

Rotary paddle accessories are used for a variety of reasons;

- Paddles are the extension of the rotary bin level indicator shaft into the material and this device contacts the material in the bin when present. The density and particle size relate directly to the paddle to be used, along with mounting criteria.

- Couplings provide a method for connecting the rotary unit output shaft to the paddle when a fixed paddle is to be used.

- Mounting plates are accessory items that aid in the installation of the rotary paddle bin level indicator assembly that utilizes a non-insertable paddle (cannot be inserted through the process connection coupling on the bin wall due to its physical size and shape).

The proper choice and use of a paddle and other type of accessory is important to the success of your installation.

Principal of Operation

For several decades rotary paddle technology has been used as a method for detecting the presence and absence of bulk solid materials.

A robust synchronous motor drives a stainless steel output shaft at approximately 1 RPM. The paddle is attached to the shaft and rotates freely in the absence of material within the bin.

Material presence surrounding the paddle in the bin will impede its rotation and cause the state of the built-in relay contacts to change, indicating material presence. The built-in LED’s will change to indicate the status of the alarm condition.

Application and Use

High (full), low (empty), intermediate (demand) level indication, and plugged chute detection, are common applications within a wide variety of industries.

Prevention of bin overfilling and material outage conditions are typical uses of these devices. The Model RH and RHX rotary paddle bin level indicators can be used to detect materials with density from 5lbs/ft³ (80kg/m³) for low and intermediate level control applications and from 10lbs/ft³ (160kg/m³) for high level indication.

Example materials include plastic pellet, food stuffs, feed and their ingredients, grains, cement, aggregate materials, nuts, flour, resins, sand, coal, chemicals, limestone, wood, sawdust and many more.

Technical Data

| Housing | Die-cast aluminum, FDA compliant powder coat, NEMA Type 4X, IP65 |

| Process Temp | Up to 300° F (149° C) |

| Ambient Temp | -40° F to +158° F (-40° C to +70° C) |

| Sensitivity | Low Level ≥ 5lbs/ft³, High Level ≥ 10lbs/ft³, Adjustable setting |

| Motor Voltage | 24VAC, 115VAC, 230VAC, 12VDC or 24VDC |

| Output | DPDT Relay, 8A @ 250VAC |

| Process Connection | 1-1/4″ NPT powder coated |

| Bearings | Four (4) sealed bearings |

| Certifications | Ordinary Location; CE mark; Hazardous Location |

More Information

Click here to download product line PDF’s

Model RH/RHX Rotary Paddle Accessories

Rotary paddle accessories are used for a variety of reasons;

- Paddles are the extension of the rotary bin level indicator shaft into the material and this device contacts the material in the bin when present. The density and particle size relate directly to the paddle to be used, along with mounting criteria.

- Couplings provide a method for connecting the rotary unit output shaft to the paddle when a fixed paddle is to be used.

- Mounting plates are accessory items that aid in the installation of the rotary paddle bin level indicator assembly that utilizes a non-insertable paddle (cannot be inserted through the process connection coupling on the bin wall due to its physical size and shape).

The proper choice and use of a paddle and other type of accessory is important to the success of your installation.

Ordering Information

Sensor Final Assembly Part Number Structure

Ordering Information

Sensor Final Assembly Part Number Structure

1 – 115VAC

2 – 230VAC

3 – 24VAC

4 – 12VDC

5 – 24VDC

1- Ordinary Location

2- Hazardous Location

1- None

2- Standard Coupling

3- Optional Coupling

1- 1-1/4″ NPT aluminum

1- Standard

2- High

1 – 115VAC

2 – 230VAC

3 – 24VAC

4 – 12VDC

5 – 24VDC

1- Ordinary Location

2- Hazardous Location

1- None

2- Standard Coupling

3- Optional Coupling

1- 1-1/4″ NPT aluminum

1- Standard

2- High