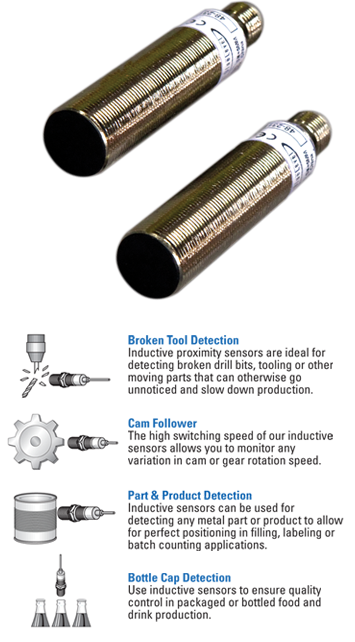

MODEL IPH

Inductive Proximity Switch

Reliable, Compact and Affordable! Proximity sensor technology for metallic objects. Inductive proximity sensors detect the presence and absence of conductive metal objects in a wide variety of automation applications in many different industries. The IPH is available in AC or DC voltage operation and normally open or normally closed.

AC or DC switches – versatile

Shielded construction for flexible mounting

Solidstate – no moving parts

Industry standard M18 size – convenience

MODEL IPH

Inductive Proximity Switch

Reliable, Compact and Affordable! Proximity sensor technology for metallic objects. Inductive proximity sensors detect the presence and absence of conductive metal objects in a wide variety of automation applications in many different industries. The IPH is available in AC or DC voltage operation and normally open or normally closed.

AC or DC switches – versatile

Shielded construction for flexible mounting

Solidstate – no moving parts

Industry standard M18 size – convenience

Principal of Operation

The inductive sensor’s circuit consists of a coil of copper wire wrapped on a ferrite core and a transistorized circuit. A small amount of energy is supplied to the coil and the transistorized circuit uses this coil to produce an oscillation. The inductive sensors operate on a “kill oscillator” principle. When the conductive material or object is brought into the Radio Frequency field, eddy current losses draw energy from the coil to run along the surface of the metal. Since there is little energy in the coil, the amplitude of the oscillation decreases as more of the target metal enters the field. When enough metal enters the field the losses become so great that the circuit is unable to keep the oscillator running. When the oscillation is killed a detector produces a solid state switch output.

Application and Use

Inductive proximity switches can be used to detect conductive metal objects. The maximum sensing distance is based upon an iron target and reduced dependent on the actual metal to be detected. Shielded construction is the most commonly available and these sensors include a metal band which surrounds the ferrite core and coil arrangement which helps direct the electromagnetic field to the front of the sensor allowing the sensor to be embedded. Unshielded sensors do not have this and are side sensitive. Inductive sensors can be used for a wide variety of purposes in detecting metal objects including detecting broken drill bits, variation in cam or gear rotation speed, part or product detection for position sensing and many other purposes.

Technical Data

| Housing | 18mm dia. x 78mm long; PBT face; Chromed Plated Brass Housing, IP67 |

| Process Temp | -13° F to +158° F (-25° C to +70° C) |

| Ambient Temp | -13° F to +158° F (-25° C to +70° C) |

| Sensing Distance | Up to 5mm Distance |

| Maximum Load | AC – 400mA, DC – 200mA |

| Process Connection | 18mm Threaded; |

| Certification | Ordinary Location; CE mark |

More Information

Click here to download product line PDF’s

Standard Models Available

- 2-Wire AC, N.O., Shielded, Connector

- 2-Wire AC, N.C., Shielded, Connector

- 3-Wire DC, PNP, N.O., Shielded, Connector

- 3-Wire DC, PNP, N.C., Shielded, Connector

- 3-Wire DC, NPN, N.O., Shielded, Connector

- 3-Wire DC, NPN, N.C., Shielded, Connector

Principal of Operation

The inductive sensor’s circuit consists of a coil of copper wire wrapped on a ferrite core and a transistorized circuit. A small amount of energy is supplied to the coil and the transistorized circuit uses this coil to produce an oscillation. The inductive sensors operate on a “kill oscillator” principle. When the conductive material or object is brought into the Radio Frequency field, eddy current losses draw energy from the coil to run along the surface of the metal. Since there is little energy in the coil, the amplitude of the oscillation decreases as more of the target metal enters the field. When enough metal enters the field the losses become so great that the circuit is unable to keep the oscillator running. When the oscillation is killed a detector produces a solid state switch output.

Application and Use

Inductive proximity switches can be used to detect conductive metal objects. The maximum sensing distance is based upon an iron target and reduced dependent on the actual metal to be detected. Shielded construction is the most commonly available and these sensors include a metal band which surrounds the ferrite core and coil arrangement which helps direct the electromagnetic field to the front of the sensor allowing the sensor to be embedded. Unshielded sensors do not have this and are side sensitive. Inductive sensors can be used for a wide variety of purposes in detecting metal objects including detecting broken drill bits, variation in cam or gear rotation speed, part or product detection for position sensing and many other purposes.

Technical Data

| Housing | 18mm dia. x 78mm long; PBT face; Chromed Plated Brass Housing, IP67 |

| Process Temp | -13° F to +158° F (-25° C to +70° C) |

| Ambient Temp | -13° F to +158° F (-25° C to +70° C) |

| Sensing Distance | Up to 5mm Distance |

| Maximum Load | AC – 400mA, DC – 200mA |

| Process Connection | 18mm Threaded; |

| Certification | Ordinary Location; CE mark |

More Information

Click here to download product line PDF’s

Standard Models Available

- 2-Wire AC, N.O., Shielded, Connector

- 2-Wire AC, N.C., Shielded, Connector

- 3-Wire DC, PNP, N.O., Shielded, Connector

- 3-Wire DC, PNP, N.C., Shielded, Connector

- 3-Wire DC, NPN, N.O., Shielded, Connector

- 3-Wire DC, NPN, N.C., Shielded, Connector

Ordering Information

Sensor Final Assembly Part Number Structure

Ordering Information

Sensor Final Assembly Part Number Structure

2 – Shielded, Quick Disconnect

1 – 2-wire AC

2 – DC NPN 3-wire

3 – DC PNP 3-wire

1 – Normally Open

2 – Normally Closed

1 – Ordinary Location

2 – M18 (18mm)

2 – Shielded, Quick Disconnect

1 – 2-wire AC

2 – DC NPN 3-wire

3 – DC PNP 3-wire

1 – Normally Open

2 – Normally Closed

1 – Ordinary Location

2 – M18 (18mm)